Parameter teknologi

| Model | ACCURL-3015-500W | ACCURL-3015-800W |

| Gelombang laser | 1080 mm | 1080 mm |

| lasing midium | YVO4 | YVO4 |

| jembaré baris min | <0,15 mm | <0,15 mm |

| nyopir | dual drive | dual drive |

| kacepetan travel max | 60m / mnt | 60m / mnt |

| area kerja maks | 3000 * 1500mm | 3000 * 1500mm |

| Z sumbu | 120mm | 120mm |

| ketebalan pemotongan baja karbon | 6mm | 8mm |

| voltase | 380V / 50HZ | 380V / 50HZ |

Mesin laser Serat collocates karo generator laser majeng kang emits sinar laser karo Kapadhetan energi dhuwur. Sinar laser fokus ing permukaan benda kerja minangka facula fokus ultrafine lan nyebabake wilayah sing disinari kanthi cepet ilang lan nguap. Sistem CNC kanthi otomatis ngontrol pemotong laser kanggo entuk misi pemotongan.

The laser equipment is constituted with the advanced laser technology, CNC technology and mechanical technology. It's applicable to processing metal sheets such as stainless steel, carbon steel, copper, aluminum and metal pipes. It has been widely used in plate processing, machinery manufacturing, and precision processing, etc.

Kaluwihan saka Mesin Nglereni Serat laser

1) Kualitas balok sing apik: Dhiameter fokus sing luwih cilik lan efisiensi kerja sing dhuwur, berkualitas tinggi.

2) Kacepetan nglereni dhuwur: Kacepetan nglereni luwih saka 45m / min

3) Stabil mlaku: Ngadopsi laser serat impor ndhuwur, kinerja stabil, bagean utama bisa nganti 100 jam;

4) efisiensi konversi fotoelektrik: Dibandhingake karo mesin pemotong laser CO2, mesin nglereni laser serat kaping telu efisiensi konversi fotoelektrik

5) Dhuwur biaya & Pangopènan sithik: Ngirit energi lan nglindhungi lingkungan. Tingkat konversi fotoelektrik nganti 25-30%. Konsumsi listrik listrik sing murah, mung sekitar 20% -30% mesin pemotong laser CO2 tradisional. Transmisi garis serat ora kudu nggambarake lensa, ngirit biaya pangopènan;

6) Gampang operasi: transmisi garis serat, ora ana laras karo cara optik;

7) Efek optik super fleksibel: Desain kompak, gampang kanggo syarat manufaktur fleksibel

8) Dual drive: beda mesin drive tradisional, daya drive dual luwih gedhe, kacepetan luwih cepet lan prosesi dhuwur

Bahan kanggo Mesin Nglereni Serat laser:

Utamane digunakake kanggo nglereni baja karbon, baja silikon, stainless steel, alloy aluminium, alloy titanium, sheet baja galvanis, papan pickling, piring seng aluminium, tembaga lan pirang-pirang jinis bahan logam nglereni lan liya-liyane.

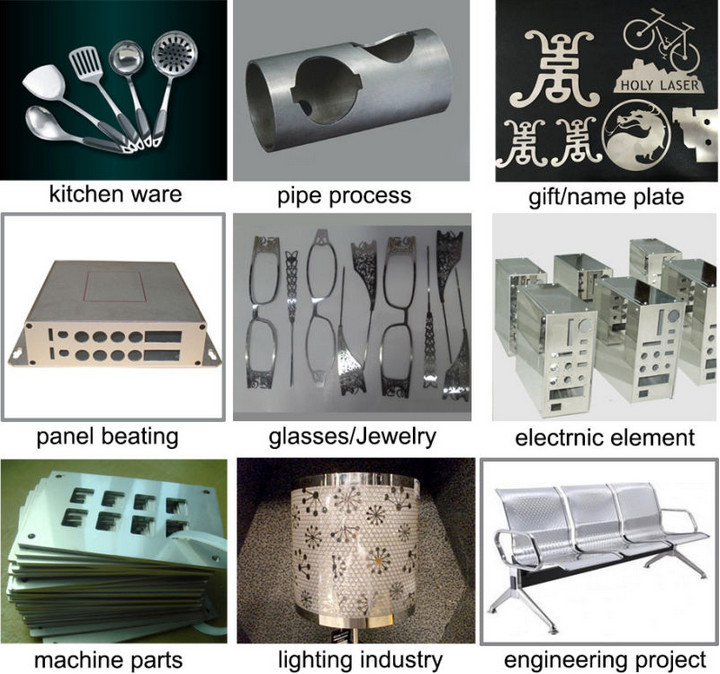

Industri Terapan saka Mesin Nglereni Serat laser:

Digunakake ing pangolahan logam lembar, penerbangan, ruang angkasa, elektronik, peralatan listrik, bagean subway, mobil, mesin, komponen presisi, kapal, peralatan metalurgi, lif, peralatan rumah tangga, hadiah lan kerajinan, pangolahan alat, adornment, iklan, pamrosesan manca logam macem-macem industri pangolahan industri.

Data Teknikal saka Mesin Nglereni Serat laser

| Daya Laser | 500W / 800W / 1000W / 2000W |

| Sumber Laser | MAX/IPG/Rayco/SPI (Pilihan) |

| Jenis Laser | Serat Laser |

| Teknologi Laser | Teknologi Jerman |

| Wilayah XYZ | 1500 * 3000 mm * 130 mm |

| Maks. Ketebalan Pemotongan (Baja Karbon) | 6-8 mm |

| Max. Nglereni Kacepetan | 0-45 Meter / Min (nganti bahan) |

| Gelombang laser | 1080nm |

| Ambane garis minimal | ≤0.15mm |

| Lokasi tliti | 0.0 ± 0,05mm |

| Lokasi presisi maneh | ± 0,02mm |

| Max. kacepetan obah | 60m / mnt |

| Format Dhukungan | PLT, DXF, BMP, AI |

| Panjaluk tenaga | 380V / 50Hz |

| Cara Ngering | Kelangan banyu |

| Pakaryan maksimal. ngemot | 1000KGS |

| Cara Pangiriman | Transmisi Screw Ball |

| Sistem sing didorong meja | Motor Servo Panasonic Impor Jepang & Sistem Nyopir |

| Cara Fokus | Dipuntedahaken lan Otomatis Laras Fokus |

| Cara Ngontrol | Kontrol Gerak Offline |

| Piranti lunak kontrol | Piranti Lunak Pemotongan Laser Cypcut |

Info dhasar

Laser Technology: Laser Control Fault Cutting

Laser Power: 500W/800W

Laser Wavelength: 1080mm

Working Size: 3000*1500mm

Lasing Midium: Yvo4

Min Line Width: Less 0.15mm

Max Travel Speed: 60m/Min

X Axis Route: 3000mm

Y Axis Route: 1500mm

Z Axis Route: 120mm

Carbon Steel Cutting Thickness: 6mm/8mm

Tandha dagang: ACCURL

Transport Package: Continer

Specification: FCC, SGS, FDA, CE, ISO

Asal: Anhui, China

Kode HS: 8456100090