Pambuka Produk

Our mesin nglereni laser serat collocates with the advanced laser generator which emits laser beam with high energy density. The laser beam is focused on the surface of workpiece as an ultrafine focus facula and causes the irradiated area instantly melted and vaporized. Automatically controls the laser cutter to achieve the cutting mission. The laser equipment is constituted with the advanced laser technology, CNC technology and mechanical technology. It's applicable to processing metal sheets such as stainless steel, carbon steel, copper, aluminum and metal pipes. It has been widely used in plate processing, machinery manufacturing, and precision processing, etc.

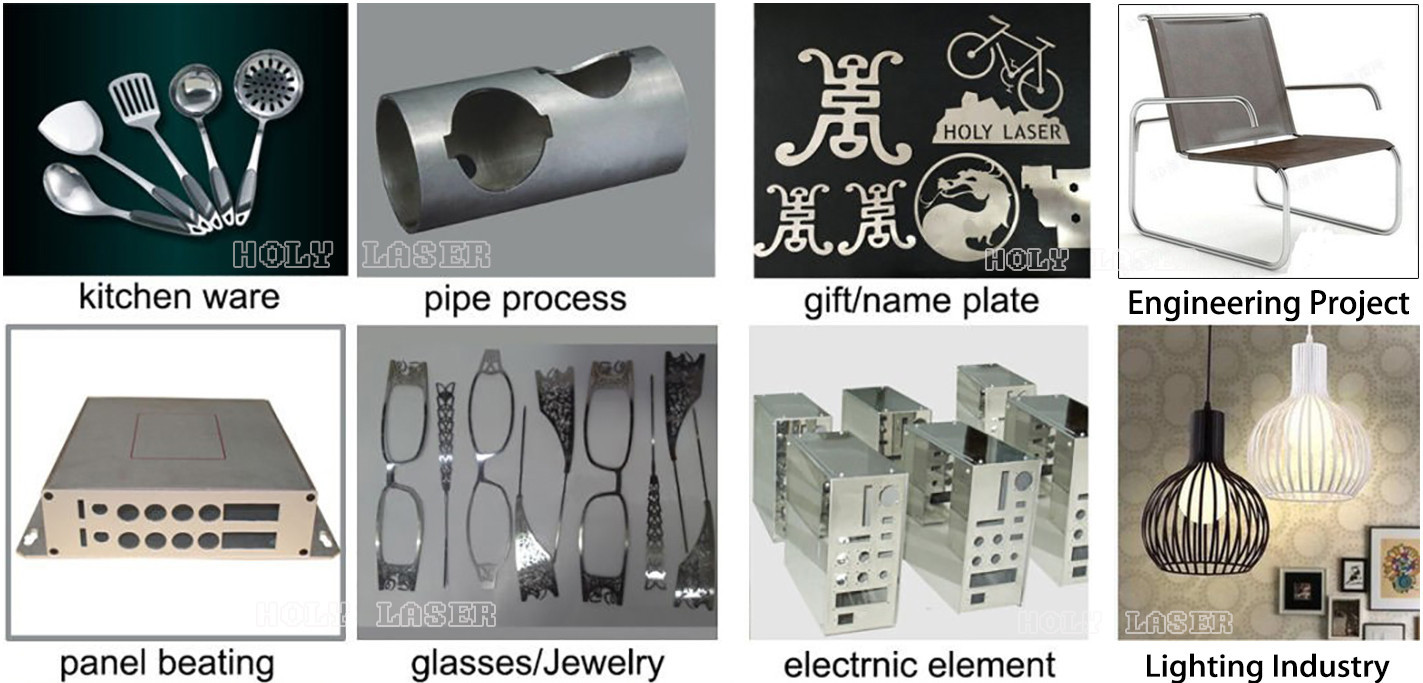

Industri Terapan

Our metal laser cutting machine applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

Bahan sing wis digunakake

Our mesin nglereni laser mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

Kaluwihan saka Mesin Nglereni Serat laser

1) Kualitas balok sing apik: Dhiameter fokus sing luwih cilik lan efisiensi kerja sing dhuwur, berkualitas tinggi.

2) Kacepetan nglereni dhuwur: Kacepetan nglereni luwih saka 45m / min

3) Stable running: Adopting the top world import fiber lasers, stable performance, key parts can reach 100,000 hours

4) efisiensi konversi fotoelektrik: Dibandhingake karo mesin pemotong laser CO2, mesin nglereni laser serat kaping telu efisiensi konversi fotoelektrik

5) Low cost & Low maintenance: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine. Fiber line transmission no need reflect lens, save maintenance cost

6) Easy operations: fiber line transmission, no adjustment of optical path

7) Efek optik super fleksibel: Desain kompak, gampang kanggo syarat manufaktur fleksibel

8) Dual drive: beda mesin drive tradisional, daya drive dual luwih gedhe, kacepetan luwih cepet lan prosesi dhuwur

Parameter teknis

| Model No | ACCURL 500W-3015 |

| Daya Laser | 500W |

| Gelombang laser | 1080 mm |

| lasing midium | YVO4 |

| jembaré baris min | <0,15 mm |

| nyopir | dual drive |

| kacepetan travel max | 60m / mnt |

| area kerja maks | 3000 * 1500mm |

Z sumbu | 120mm |

| ketebalan pemotongan baja karbon | 6mm |

| voltase | 380V / 50HZ |

| Cara Ngering | Kelangan banyu |

| Lokasi tliti | 0.0 ± 0,05mm |

| Format Dhukungan | PLT, DXF, BMP, AI |

| Pakaryan maksimal. ngemot | 1000KGS |

| Cara Pangiriman | Transmisi Screw Ball |

| Sistem sing didorong meja | Motor Servo Panasonic Impor Jepang & Sistem Nyopir |

| Cara Fokus | Dipuntedahaken lan Otomatis Laras Fokus |

| Cara Ngontrol | Kontrol Gerak Offline |

| Piranti lunak kontrol | Cypcut Laser Cutting Software |