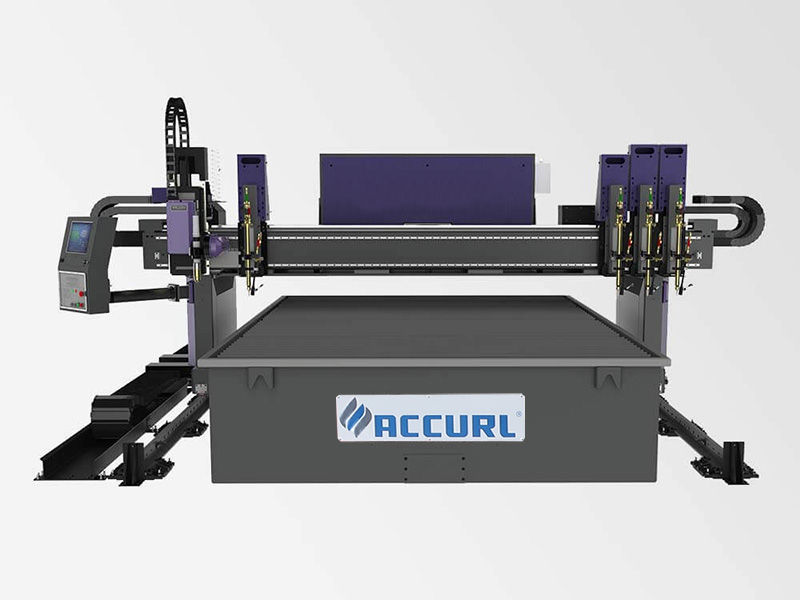

Fitur

(1) Gawe gampang

(2) Two cutting ways: flame or plasma available.

(3) Tidy cutting surfaces without burr, cutting speed can achieve to 6000mm/min.

(4) Sistem servo nyetir kaping pindho, njamin kinerja sing apik banget.

(5) Tabel pakaryan bukti bledug utawa asap njabut piranti kanggo lingkungan kerja sing resik.

(6) Daya plasma pilihan kanggo nglereni bahan sing beda.

(7) German Neugart planetary reducer for transimission which is characterized of bigger toque, low gap and free maintenance.

Rincian cepet

Kondisi: Anyar

Nomer Model: mesin nglereni plasma cnc/Kaliburn Kjellberg

Voltage: 380V 50HZ

Daya Rated: 5.5kw

Dimension(L*W*H): 3x8m

Weight: 1600kg

Sertifikasi: CE ISO

Waranti: 1 Taun

Layanan sawise adol sing diwenehake: Engineers kasedhiya kanggo mesin layanan ing luar negeri

Name: cnc plasma cutting machine/Kaliburn Kjellberg

Cutting mode: Plasma and Flame

Cutting thickness: plasma 0-55mm ; flame 6-200mm

Cutting speed: plasma 0-4000mm/min ; flame 0-750mm/min

Drive system: Panasonic AC servo motor

Control system: USA or China brand

Plasma power: USA or China brand

THC: USA or China brand

Nesting and programming: FastCAM

Main Parameters

| Ora | item | spésifikasi | ||||||

| 1 | Horizontal track space(mm) | 4000 | 4500 | 5000 | 5500 | 6000 | 6500 | 7000 |

| 2 | effective cuttin width(mm) | 3200 | 3700 | 4200 | 4700 | 5200 | 5700 | 6200 |

| 3 | Overall width (mm) | 4800 | 5300 | 5800 | 6300 | 6800 | 7300 | 7800 |

| 4 | Cutting mode | flame only,plasma only,flame and plasma | ||||||

| 5 | Driving method | rack and pinion drive for X and Y axes | ||||||

| 6 | Driving mode | single/double-side driving | ||||||

| 7 | Flame cutting thickness | 6-200mm | ||||||

| 8 | Plasma cutting thickness | 0-55mm(depends on plasma power source) | ||||||

| 9 | Kacepetan nglereni | 0-4000mm/min | ||||||

| 10 | Empty stroke speed | 0-10000mm/min | ||||||

| 11 | Automatic height controller | capacitive height control for flame cutting arc voltage height control for plasma cutting | ||||||

| 12 | Cutting gas | acetylene,propane(optional) | ||||||

| 13 | Plasma gas | pressed air,oxygen,N2 | ||||||

| 14 | Marking tool (Optional) | yes (Optional) | ||||||

| 15 | Nesting softwar (optional) | Integnps,Fast cam | ||||||

Akurasi Mekanik

1. akurasi instalasi rel pandhuan:

1) Straightness accuracy of main rail ±0.2mm/10m

2) levelness between two rails ±0.5mm/10m

3) Tahap longitudinal ril utama ± 0.2mm / m; ± 2mm / sakabèhé dawa

4) Parallelism between two rails <±2mm/ rail space

2. Mesin tliti:

a. Longitudinal effective stroke >nominal size 20mm

b. Transverse effective stroke > nominal size 10mm

c. Linear positioning accuracy ±0.1mm/10m

(1000×1000mm Comprehensive graphics detection) GB deviation≤±0.3mm

d. Linear repeat accuracy ±0.4mm/10m

e. Torch stroke ≤170mm

f. Cutting speed ±5% of setting speed

g. Automatic lifting precision ±0.5mm

3. presisi mesin komprehensif:

a. Length deviation(four sides) 0.3mm

b. Diagonal deviation 0.3mm

c. Back to the origin of the deviation 0.2mm

d. Diagonal straightness accuracy 0.3mm

e. Intersection deviation 0.3mm

f. Linear deviations 0.2mm

g. Entire machine positioner precision 0.1mm