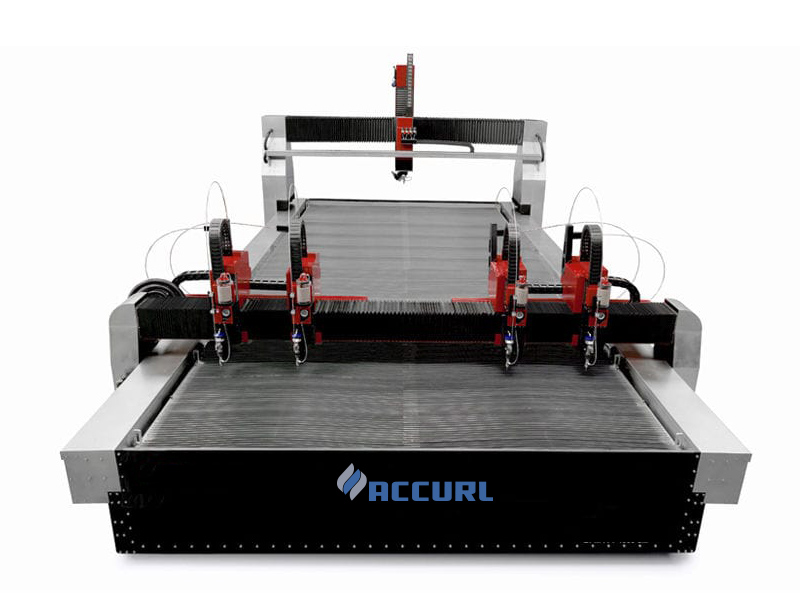

Katrangan Product Detailed

| Nomer Model: | ACCURL-1515L Mesin Motong Jet CNC | Wilayah Motong sing efektif (Length): | 1500mm |

|---|---|---|---|

| Wilayah Motong sing efektif (jembar): | 1500mm | Total Electric Power: | 38KW |

| Lumahing Atos: | Ra≤25μm | Kata kunci: | Mini Water Jet Cutting Machine |

Mini Water Jet Cutting Machine for metal marble granite tile leather and compound material

Katrangan Product

Ing ACCURL mesin waterjet abrasive yaiku mesin waterjet tekanan dhuwur sing nggunakake pemotongan banyu langsung utawa pemotongan waterjet abrasif kanggo ngethok sawetara jinis materi. ACCURL Water-Jet minangka presisi tugas abot, sistem dirancang sekrup werni lemah kanggo presisi lan kaku maksimal.

Pemotongan Waterjet Sampurna:

Mesin machining ACCURL® bisa digayuh kanthi meksa banyu akeh ing tekanan sing dhuwur liwat orifice cilik ing muncung pemotong. Udakara banyu sing nyepetake ninggalake nozzle ngetrapake materi lan miwiti proses pemotongan. Kerf saka aliran banyu sing nyepetake banget sempit. Tekanan iki banjur klempakan ing area cilik ing materi sing wiwit njeblug materi kasebut. Bahan padu bisa dipotong kanthi tekanan banyu. Bahan sing luwih angel mbutuhake panggunaan sistem feed abrasive, kayata nglereni logam. Abrasive dikenalake menyang aliran banyu tekanan tinggi, sing banjur wiwit erosi bahan-bahan sing luwih angel. Sanajan pemesinan waterjet minangka proses sing paling alon, nanging ana kaluwihan sing pasti luwih gedhe:

1. Ora ana Zona sing kena pengaruh Panas

2. Ora Tekanan Mesin

3. Banget Panah Kerf

4. No need for Secondary Operations

5. Smooth Surface

6. Can Cut Various Materials

7. Can Process Extremely Detailed Parts

8. Minimal loss of material

9. Environmentally Friendly

Fitur Utama

1. Bisa nransfer gambar kanggo nglereni kanthi cepet

2. Posisi cepet-sawetara utawa sawetara peralatan mbenakake

3. Hing akurasi-ngurangi recutting

4. Kacepetan nglereni luwih cepet

5. Ora perlu pabrikan kanggo bagean kerja

6. Luwih aman kanggo operator lan kahanan osteam, bledug, smog etc

7. Kelangan nglereni-ora panas bakal prouduced

8. Clear Processing, ing ora perlu mbusak bagean apa maneh

9. Good nglereni rampung-ing ora perlu saka trimina nglereni rampung maneh

10. Celah nglereni sempit

11. Kalibrasi cepet lan cara versatility luwih gampang nglereni. Wis dibuktekake manawa bisa digunakake ing produksi massal ing sistem becik

12. Pas kanggo piranti lunak CAD / CAW

13. Waterjet cutting machine can cut almost all the materials.It can cut the foilat the thickness of 200mm

Sistem

Sistem Hp: WJPOWER-420D (Dual-intensifier HP System)

Max.Pressure: 420Mpa

Laju Alir Maks: 7.4L/min

Daya Listrik: 75KW/100HP

Tegangan: 220V ~ 480V / 50,60HZ.3PH

Déwan Intensifier diimpor kanthi lengkap saka KMT (H20 USA)

HIGH PRESSURE SYSTEM

Experience a new level of uptime and productivity with the WJ POWER 500, your total cutting solution. Combining unmatched accuracy with the fastest acceleration in waterjet, the WJ POWER 500 will elevate your cutting production and performance levels.

MAIN FEATURES

1. Control: PLC

2. Shifting: electro-hydraulic control

3. Cooling: cooler/oil heat exchanger

4. In let water filter accuracy : ≤ 0.45μm

5. Oil-return filter accuracy: 20μm

6. Working temp:0-60℃

7. Outlet:UNF3/8’’

8. Cooling in/out-let:NPT 1’’

9. Max orifice size:0.33mm

characteristic

1. Functional characteristic

1. The cutter head inclined at an angle in any direction,eliminating the phenomenon f concave convex and uneven cutting surface(to eliminate phenomenon of small surface and large bottom).To make the front junction smaller, reduce grinding link,can tile diretly.Reducing the polished and the production cost greatly.

2. Make the complex graphics more delicate and beautiful.

3. It turning without pause,no turning dot,make cutting speed faster.The cutting surface roughness wil not affect the collage.

2. Processing characteristic

1. CNC forming complex patterns.

2. Environmental pollution,no toxic gases and dust.

3. Can process a variety of high hardness material ,such as :glass,ceramics,stainless steel,or relatively soft material ,leather,rubber,diapers,etc.

4. Cutting smooth,no slag,doesn't need secondary processing.

5. Save the cost.

Spesifikasi

| Model | ACCURL-1515L | ||

| meja kerja | mm | 1500 x 1500 | |

| Sumbu X-s | stroke | mm | 1500 |

| Kacepetan | m/min | 0~15 | |

| Y-sumbu | stroke | mm | 1500 |

| Kacepetan | m/min | 0~15 | |

| Z-sumbu | stroke | mm | 150-180 |

| Kacepetan | m/min | 0~12 | |

| Akurasi kontrol | mm | ± 0,01 | |

| Posisi akurasi | mm | ± 0,02 | |

| Sistem Tekanan Dhuwur | Tekanan maksimal | Mpa | 380 |

| Kuwasa | Kw | 37 (50HP) | |

| Kekuwatan listrik total | KW | 38 | |

| Tabel maksimal meja | Kg | 1000 | |

| Format didhukung | AI, PLT, DXF, lsp | ||

| Bobot mesin | Kg | 2550 | |

| Ukuran njaba | mm | 2050x1850x1850 | |

| Jeneng Produk | Mini Water Jet Cutting Machine | ||