Fungsi

(1)Coil material straightening and leveling

(2)Synchronous material loading and cutting

(3)Belt-drive and automatic material loading

Rincian cepet

Aplikasi: Motong Laser

Kondisi: Anyar

Jenis Laser: Serat laser

Bahan sing ditrapake: Logam

Ketebalan pemotongan: 20 mm

Wilayah Nglereni: 1500 * 3000mm

Kacepetan Motong: 35m / min

CNC utawa Ora: Ya

Mode Kelangan: Pengering banyu

Piranti Lunak: Cypcut

Format Grafis Didhukung: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Certification: CE, ISO, SGS, FDA,BV

Layanan sawise adol sing diwenehake: Engineers kasedhiya kanggo mesin layanan ing luar negeri

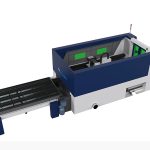

Function: cnc metal laser cutting machine

Working Area: 1300x3000mm

Laser Power: 500W ~4000W

Max. Ngalih Kacepetan: 100m / min

Max. Cutting Speed: 35m/min

Positioning Accuracy: 0.03mm

Reposition Accuracy: 0.02mm

Min. Jembar Line: 0.1mm

Ngethok ambane: 0.2-6mm

Keperluan Daya: 380V / 50Hz / 16A

Fitur

(1)Integration of fully automated material straightening, leveling, loading and cutting

(2)Automatic assembling line for manpower saving

(3)Guarantee of continuity for production and processing

(4)Net coil material cutting to improve sheet metal utilization rate.

(5)Compact configuration and full-enclosure design for safer and environment-friendly operation.

(6)Rolling cutting platform to avoid material jamming during finished material conveyance

(7)Leveling machine is synchronized with rolling cutting platform for material feeding, to protect underside from scratch during material feeding.

(8)Automatic material loading is facilitated with width limit device to prevent off-track of materials with narrow or wide size and ensure alignment.

Advantage of metal cutting cnc laser machine

1. Kualitas path sing apik: Dot laser sing luwih cilik lan efisiensi kerja sing dhuwur, berkualitas tinggi.

2. Kacepetan nglereni dhuwur: kacepetan nglereni kaping 2-3 saka mesin pemotong laser CO2 sing padha.

3. Stabil mlaku: ngetrapake serat laser impor ndhuwur, kinerja stabil, bagean utama bisa nganti 100 jam;

4. Efisiensi dhuwur kanggo konversi fotoelektrik: Bandhingake karo mesin pemotong laser CO2, mesin nglereni laser serat kaping telu efisiensi konversi fotoelektrik.

5. Biaya murah: Ngirit energi lan nglindhungi lingkungan. Tingkat konversi fotoelektrik nganti 25-30%. Konsumsi listrik listrik sing murah, mung sekitar 20% -30% mesin pemotong laser CO2 tradisional.

6. Pangopènan sithik: transmisi serat serat ora perlu nggambar lensa, ngirit biaya pangopènan;

7 Gampang operasi: transmisi garis serat, ora ana laras karo cara optik.